The Technology

Netalux Needle 300W

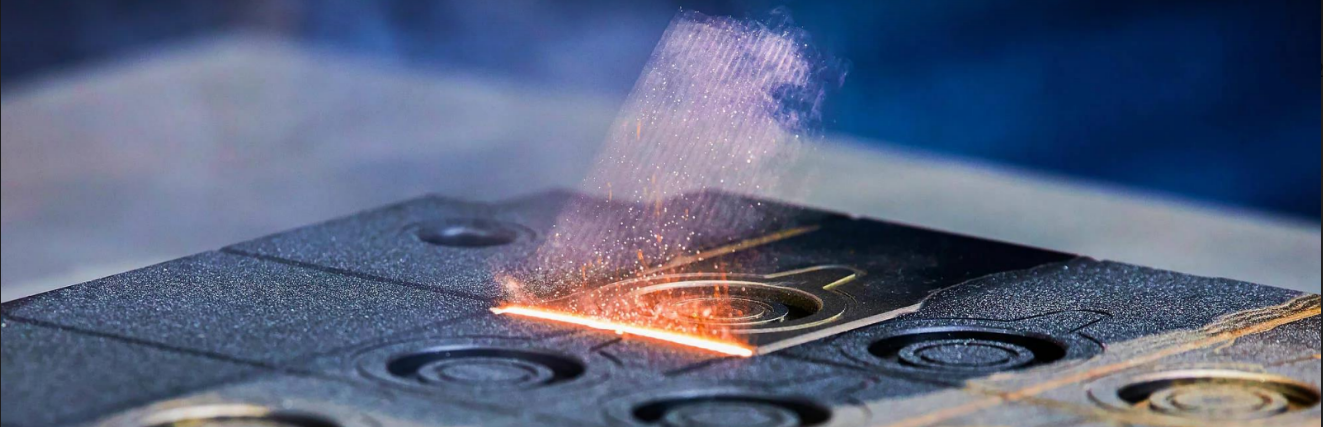

The Netalux Needle 300 Watt is a Class IV Pulsed Ytterbium

Fiber Laser designed for more aggressive and efficient laser cleaning tasks. It

offers two power options: 200 or 300 Watt.

The Needle features a Gaussian

pulse with a maximum of 2 mJ, allowing for deeper and more aggressive cleaning. The

unit is air-cooled and weighs approximately 40 kg. It comes with a longer 5.7m

fiber, providing a wider range of operational flexibility.

The Needle also

includes a multifunctional handset with an integrated user interface and LED

headlight for better visibility and control. This model is ideal for tasks requiring

a higher power output and more aggressive cleaning.

Netalux Jango 1000w

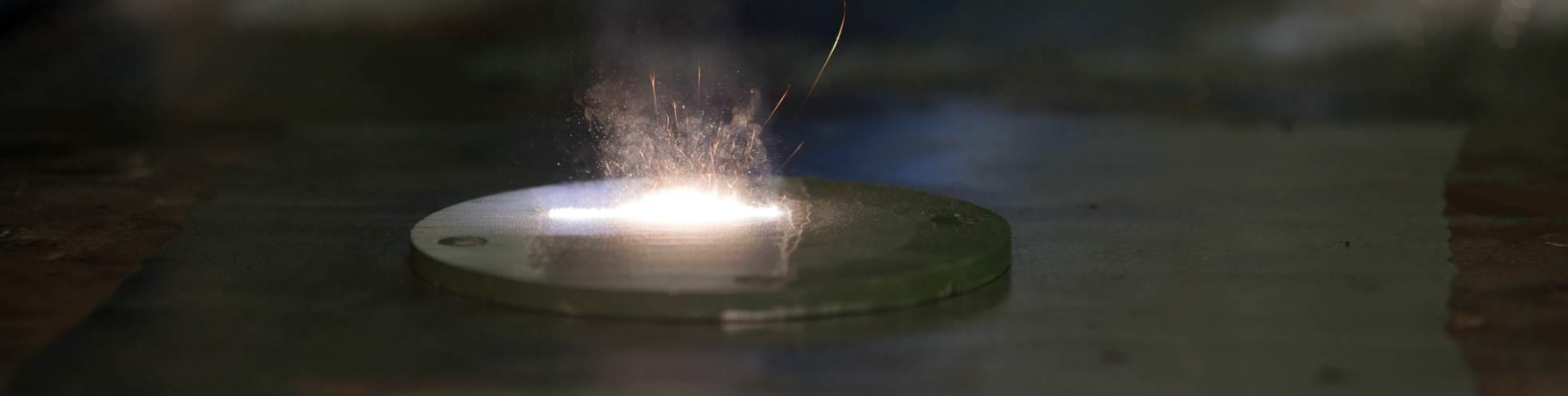

The Netalux Jango is a high-performance Class IV Pulsed Ytterbium Fiber Laser designed for efficient laser cleaning. It offers two power options: 500 or 1000 Watt, and features a Top Hat pulse for efficient cleaning of larger surfaces.The unit, weighing approximately 750 kg, is equipped with an integrated water cooling system, a 50m long fiber, and an LED headlight for better visibility. It also includes integrated controls in the handset and an ergonomic handle for comfortable operation.

Air-cooled

Compact and flexible

Water-cooled

Bigger and stronger